Transparency and efficiency through Schaeffler’s service solutions

Digital services from Schaeffler are easily accessible and increase the availability of machines and equipment as well as process quality. Thanks to Schaeffler’s unique system and modeling expertise, which covers everything from individual rolling contacts through to complete systems, product and process data can now be converted into useful information. Process parameters are provided, specific statements made about machine conditions, and necessary measures taken in advance in the form of digital services.

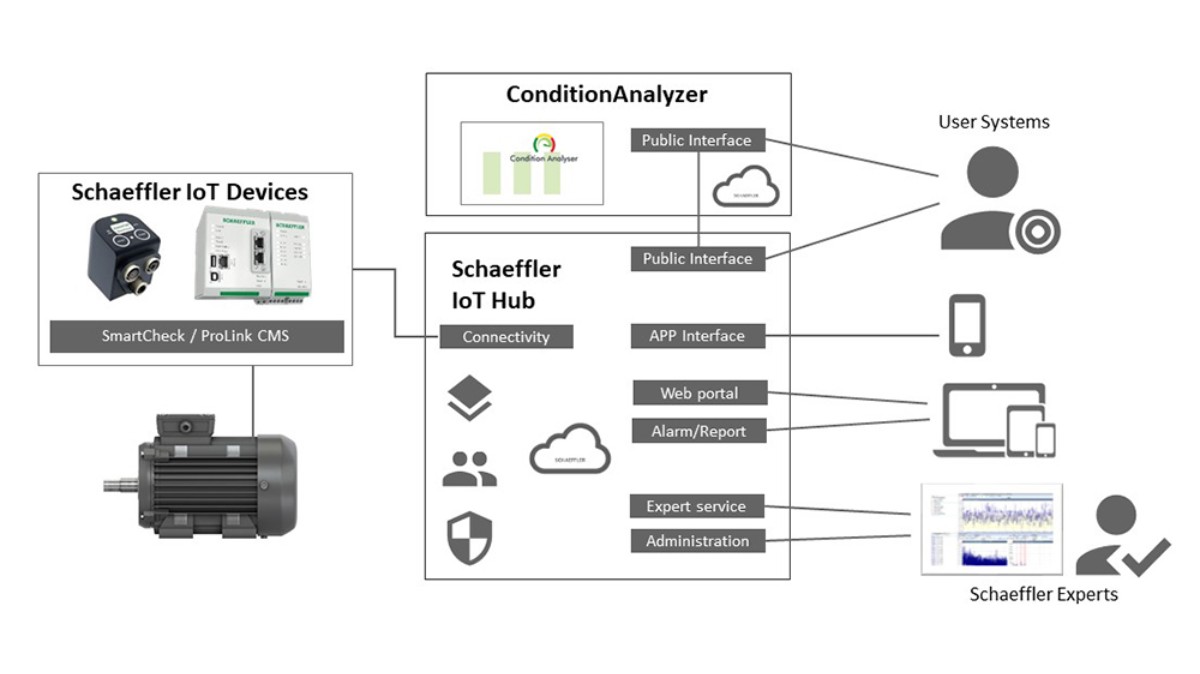

From intelligent component to cloud – Schaeffler offers a scalable high-performance IT infrastructure. The flexible and open architecture of this system offers a simple and application-oriented point of entry into Schaeffler’s range of digital services that can be expanded at any time. Easy-to-configure interfaces automatically transmit information to customer systems and give access to Schaeffler’s expertise.

SmartCheck

The SmartCheck from Schaeffler is a compact, innovative, and modular condition monitoring system for continuous, decentralized machine and process parameter monitoring. It can be used on machines and equipment where such monitoring was previously too costly.

ProLink CMS

Innovative, modular online measuring system for vibration analysis for the universal monitoring of machines

Your benefit:

- Increased machine availability

- Prevention of unplanned downtimes

- Maintenance and service personnel planning

- Prevention of subsequent damage

- Reduction of maintenance costs

- Possibility of analyzing the cause of the defect

ConditionAnalyzer

Digital service for bearing monitoring in electric motors, pumps, fans, and entire drive trains

Your benefit:

- Prevention of unplanned downtimes

- Reduction of maintenance costs

- Transparency regarding the drive train’s condition

- Simple data management

- Simple monitoring of entire fleets

Remote services

Remote diagnosis services for your machines provided by Schaeffler’s experts by means of vibration monitoring

Your benefit:

- Preventing unplanned downtimes through fast reaction times and a high level of diagnostic accuracy.

- Regular preparation of condition reports with specific recommended actions

- Alarms are given immediately via telephone or e-mail if irregularities are detected

- Individual consultation on the use of vibration monitoring systems for your machines and equipment

- Support for solving problems by accessing Schaeffler’s global network of experts

- Support from Schaeffler’s rolling bearing application engineers for optimizing your machines

ConditionAssistant

Transform your smartphone into a Condition Monitoring tool

Your benefit:

- Free download for iOS and Android devices

- Individual solution packages for your assets

- Machine diagnostics without additional sensors

OPTIME

OPTIME is a wireless IoT solution, which efficiently and cost-effectively makes the condition monitoring of auxiliary units in entire machine parks possible, and is so easy to install that several hundred Units can be integrated in one day without any problems. Automatic data Analysis based on Schaeffler expertise makes it easy for the maintenance team to schedule maintenance tasks at the right time and in a cost-efficient manner.

Further components that can be integrated into the system

SmartQB

Condition monitoring solution for electric motors, pumps, and fans

SmartQB is very easy to install and does not require any specific knowledge about vibration diagnosis. Vibration data automatically generate plain text messages on the 7-inch display. Plug-and-play solution that does not require any prior knowledge about vibration analysis

- Plug-and-play solution that does not require any prior knowledge about vibration analysis

- Preconfigured for reliable monitoring of motors, pumps, and fans

- Easy-to-understand plain text messages regarding the possible cause of the defect if irregularities are detected

- Simple initial operation in only a few minutes

- Can easily be extended by up to 6 sensors

- Plain text messages in more than 15 languages

- Live display of current values

GreaseCheck

Online grease monitoring helps to minimize bearing failures

Your benefit:

- Current information on the condition of bearings’ grease

- No outlay for manual sampling and grease analysis

- Automated and optimized requirement-based relubrication possible

- Cost savings for fresh and used greases (sustainability)

Detector III

Simple vibration route measuring system with an optional balancing function

Your benefit:

- Increased machine availability

- Prevention of unplanned downtimes

- Maintenance and service personnel planning

- Prevention of subsequent damage

- Reduction of maintenance costs

- Possibility of analyzing the cause of the defect

CONCEPT1

CONCEPT1 automatic lubricator

The CONCEPT1 is the most cost-effective starter product for automatic relubrication. This makes it ideal for a wide range of applications, and it is supplied pre-filled with Schaeffler’s high-performance ARCANOL grease or as an empty device that can be re-filled multiple times with the customer’s own lubricating grease or oil. This reduces waste, helps protect the environment, and saves maintenance costs.

CONCEPT2

Always supplying the right lubricant to the right point at the right time

Your benefit:

- Reduced outlay for complicated manual relubrication

- Reduction of time-consuming repairs due to insufficient lubrication

- Robust, easy-to-use system

- No contamination of the rolling bearing due to contaminants in the lubrication system (sealed replaceable cartridges)

CONCEPT4

CONCEPT4 automatic lubricator

This lubricator is suitable for minimum-quantity lubrication with grease. It has four lubricant supply line outlets that can be controlled in separate pairs.

CONCEPT8

Always supplying the right lubricant to the right point at the right

Your benefit:

- Reduced outlay for complicated manual relubrication

- Reduction of time-consuming repairs due to insufficient lubrication

- Robust, easy-to-use system

- No contamination of the rolling bearing due to contaminants in the lubrication system (sealed replaceable cartridges)

Consultation and contact

Would you like to know more? Then feel free to contact us.