Mining and processing

Technical advances are progressing faster and faster in the areas of mining and large conveying systems, development and extraction of crude oil and natural gas, and treatment technology. Our research and development and our intensive exchange of experiences with manufacturers and operators of machines and systems have led to greater operational safety and an ever longer operating life of INA and FAG bearings.

Applications

Advanced bearings for various systems and machines

The challenging operating and environmental conditions in the systems and machines require extremely robust bearings. Our customers build and operate ore conveyor systems, mines, cement plants, oil platforms, crushing machines, construction machinery, and construction sites.

- Mining

Bucket wheel excavators, transport systems

- Preparation

Crushers, vertical mills, tube mills, vibrating screens

- Onshore/offshore

Drilling rig units, drilling turbines, pipe-laying drums

Products

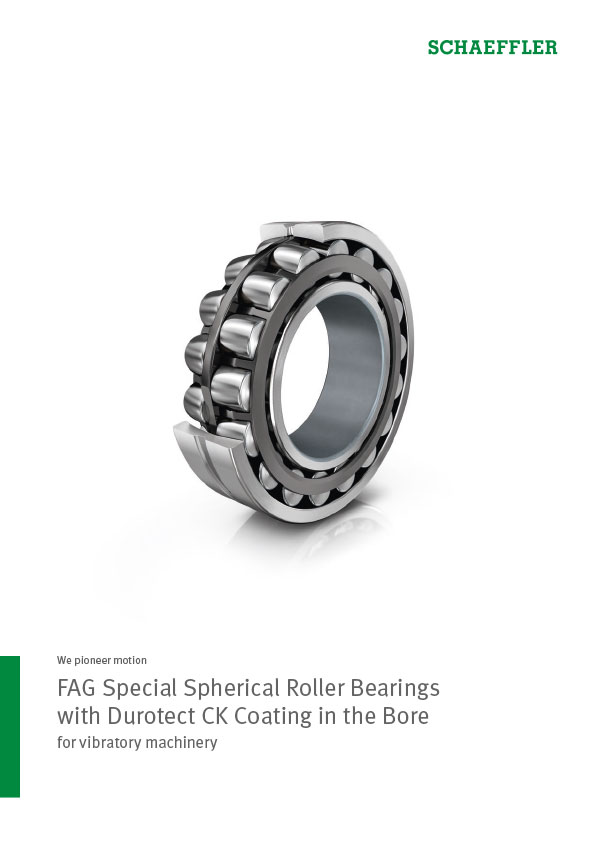

Standard designs and special bearings

The conditions in the systems and machines in the area of raw material extraction and processing are different for every application. The concepts, designs, and structures mainly depend on the loads, speeds, operating life, and environmental conditions.

For many applications, the designer is able to use rolling bearings of standard types and designs. However, some applications require special rolling bearings that we have developed for specific requirements in the industry. The largest of these bearings – used in tunnel boring machines – can have an outside diameter greater than four meters.

- Standard bearings

- Special bearings

- Housing

- Units

Service

Technical consulting, maintenance solutions, and stock management

Achieving ever shorter development times requires precision in the process of dimensioning and designing rolling and plain bearings right from the word go. This is also true in the area of raw material extraction and processing. Making use of the know-how of experienced bearing experts already during the the development phase saves our customers time and money. This is why we offer extensive consulting for designers – from technical literature to our electronic catalog to calculation programs.

Schaeffler provides a wide range of maintenance solutions for reducing maintenance costs, preventing unplanned downtimes, and increasing machine availability.

Through specially developed stock management, we supply our customers with selected products from the area of raw material extraction and processing. In this way, we are able to greatly reduce the bearing maintenance costs of our customers and ensure rapid availability at a fair market price.