Schaeffler at drinktec 2025 (Hall C4, Booth 439) Products and services for greater hygiene, efficiency, and reliability

2025-09-04 | Schweinfurt

- Schaeffler presents portfolio specially tailored to the high standards in the beverage filling segment

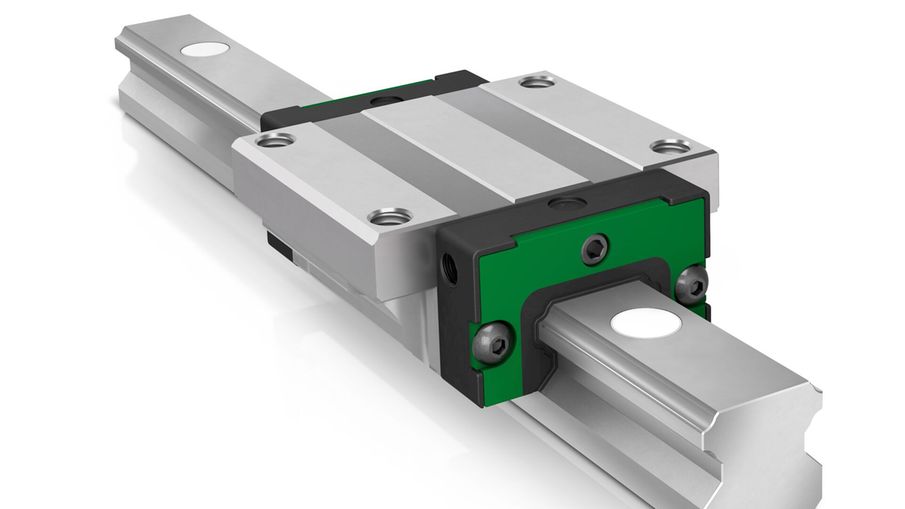

- New KUEM stainless steel miniature monorail guidance system and new KLLT four-row linear recirculating ball bearing and guideway assembly for various handling axes

- Condition monitoring solutions for the smooth and economic operation of beverage filling systems

With innovative solutions for greater reliability, efficiency and hygiene, the Motion Technology Company Schaeffler is set to present its comprehensive range of products and services for food and beverage production at drinktec 2025. As Schaeffler offers dedicated solutions along the entire process chain, its exhibit is divided into three thematic areas – processing, filling and packaging.

Food and beverage production companies generally need to reconcile stringent hygiene, maximum efficiency, high flexibility, continuous operational reliability and cost effectiveness to remain competitive while meeting consumer needs and environmental regulations. Schaeffler offers an extensive portfolio to satisfy these exacting requirements. The focus is on newly developed linear guidance systems and bearing solutions that offer increased energy efficiency, durability and precision as well as a hygienic design concept. Digital condition monitoring systems ensure more cost-efficient and trouble-free plant operation.

Filling: dynamic, heavy-duty, and efficient solutions in hygienic environments

For applications such as filling systems, which have strict hygiene standards, Schaeffler offers a range of products specifically tailored to meet the requirements of the sector. This includes the KUVE-B range of linear recirculating ball bearing and guideway assemblies with an optimized lubrication and sealing package comprising a KIT450 long-term lubrication unit, additional wipers with double lip, non-contact sheet steel wipers, and the Arcanol FOOD2 lubricant. The uniform distribution of the lubricant in the carriages also reduces the amount of lubricant needed. By using these linear guides, operators can save around 50 percent lubricant and 70 percent maintenance costs. Service lives of more than 50,000 kilometers without re-lubrication are possible.

For the numerous axial bearings and slewing rings of fillers, cappers etc., Schaeffler offers one of the largest ranges of bearings with high tilting rigidity on the market. These include SGL axial angular contact tapered roller bearings, XU crossed roller bearings with flange mounting on inner and outer ring, XV crossed roller bearings with flange mounting on outer ring, and VU four-point contact bearings.

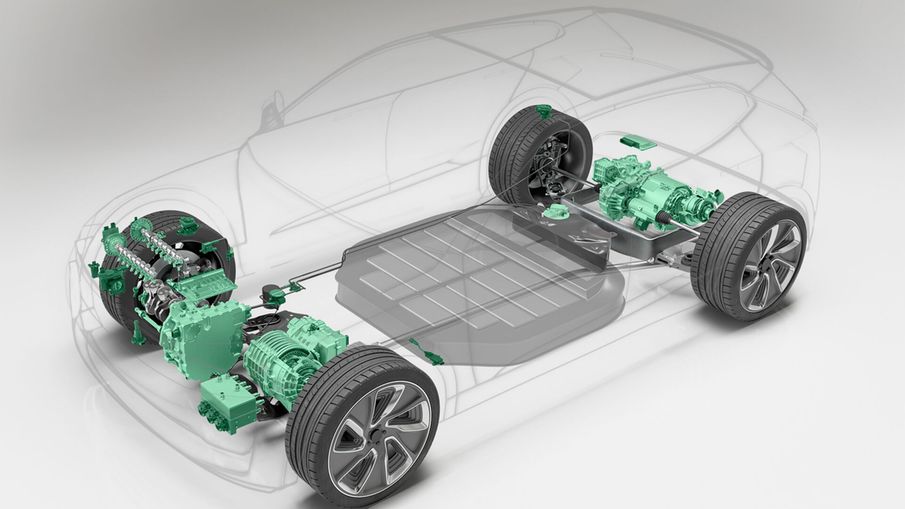

High electricity prices are having an impact when it comes to new designs for carousels, for example for starwheels, so designers are looking for new and energy-efficient drive solutions. With a direct drive like the RIB torque motor from Schaeffler, efficiencies of around 0.92 can be achieved, whereas geared motor solutions only achieve overall efficiencies of 0.73–0.75. Using this direct drive can save several tens of thousands of euros in energy costs and more than 100 tons of CO2 emissions over the life of a single beverage filling system.

Packaging: durable and proven components for maximum availability

When it comes to packaging technology, the industry is focusing primarily on durable and reliable standard components. For this purpose, Schaeffler presents its proven linear technology portfolio for the food and beverage industry, including track roller and shaft guidance systems, the new stainless steel KUEM miniature monorail guidance system, and the new KLLT four-row linear recirculating ball bearing and guideway assemblies for a wide range of handling axes. With its KLLT series, Schaeffler now offers a four-row “all-round” linear recirculating ball bearing and guideway assembly in an X arrangement for substructures with lower precision requirements, as well as a series in an O arrangement that meets strict requirements for precision, rigidity, and load-bearing capacity. Worthy of particular mention among the company’s rotary bearing solutions are its radial insert ball bearing housing units, which have a new design. Open fastening eyelets, slopes on the housing, and generous 45-degree bevels facilitate the outflow of cleaning fluids and the drying process. Thanks to the hygienic design concept, they can be cleaned very easily and have no space for undesirable bacteria to grow. The housing units come in a glass fiber reinforced plastic with FDA approval or in stainless steel, so they are both corrosion- and media-resistant. All deep groove ball bearings are in corrosion-resistant stainless steel.

Processing: your partner for smooth-running processes

With its portfolio from the Lifetime Solutions division, Schaeffler offers innovative solutions for the smooth and cost-efficient operation of beverage filling systems. The exhibit includes Schaeffler OPTIME, a self-networking, self-configuring condition monitoring system that can automatically monitor more than 90 percent of all drive systems in the beverage industry. The battery-operated system can be easily installed by operators themselves. The smart lubricator OPTIME C1 is equally innovative. By monitoring the lubricant level it makes route-based maintenance schedules superfluous and is thus revolutionizing maintenance workflows. Without requiring major investment, the extensive OPTIME portfolio enables system availability to be increased and allows a substantial reduction in maintenance costs. As a rolling bearing manufacturer, Schaeffler knows how important it is to use high-quality lubricants adapted to the application. In Munich, therefore, Schaeffler will present its Arcanol lubricating greases and the benefits they offer for wear reduction and extended service life.

With its trade fair appearance at drinktec 2025, Schaeffler is underlining its role as a reliable partner to the food and beverage industry. At the Schaeffler booth, visitors can see for themselves the company’s practical applications, industry-specific innovations, and comprehensive range of services.

Further information about Schaeffler at drinktec 2025 can be found here.

Publisher: Schaeffler Technologies AG & Co. KG, Schweinfurt

Country: Germany

Terms of use for Schaeffler press pictures

Schaeffler press pictures may only be used for editorial purposes. Unless otherwise stated, all copyrights and rights of use and exploitation are owned by Schaeffler Technologies AG & Co. KG, Herzogenaurach (Germany) or by one of its affiliated companies. The reproduction and publication of Schaeffler press pictures is only permitted if the source is stated as follows: "Image: Schaeffler". The pictures may be used free of charge in such cases. The use of pictures for advertising or other commercial purposes, in particular their disclosure to third parties for commercial purposes, is hereby prohibited. Pictures may only be edited with the approval of Schaeffler.

We kindly request that a specimen copy be sent to us when Schaeffler press pictures are published in printed media (or a digital copy in the case of publication in electronic media). When using Schaeffler press pictures in films, please notify us and state the title of the film.

Use and utilization of Schaeffler press pictures is subject to the substantive laws of Germany without its conflict of law provisions. The place of competent jurisdiction shall be Nuremberg, Germany.

Postal address:

Schaeffler Technologies AG & Co. KG

Corporate Communication

Industriestrasse 1-3

91074 Herzogenaurach

Germany

Press releases

Package (Press release + media)