The transportation sector is facing disruption across the board from unsustainable global air, land, and water pollution levels. According to a report from the European Environment Agency, transport was responsible for a quarter of the EU’s total CO2 emissions in 2019, with 71.7 per cent of that quarter coming from road transportation. Without the transportation and logistics sector making significant changes, achieving the global climate goals will not be possible, especially since CO2 emissions standards will be tightened again.

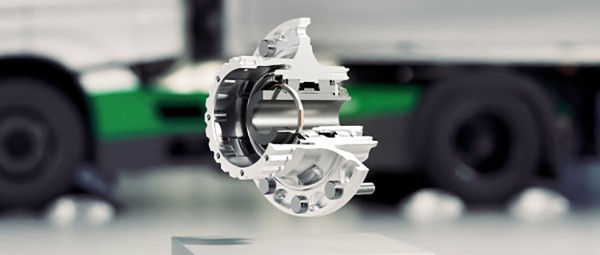

To address these concerns in the transport industry, Schaeffler is developing efficient solutions for its bearings that offer plenty of efficiency and innovation potential. They can reduce friction, therefore noticeably lower the consumption of commercial vehicles. In particular, its wheel bearings, having been upgraded with smart sensors, have become an essential element of automated driving and digital services.

Defective tyres or brakes are currently causing about 40 per cent of vehicle downtime. By the use of condition monitoring as a means of measuring wheel forces, braking forces, vibrations, and temperatures at the wheel head within fractions of a second, that rate would drop significantly.

Schaeffler is planning to help digitise trucks and accelerate the development of automated driving with an intelligent wheel bearing. With integrated smart sensors, the technical condition of the bearing and wheels can be monitored remotely. The data gathered can then be used for automated driving and digital services. Additionally, using the data acquired further allows for early detection of when cargo has fallen or shifted in transit and road conditions to be derived.

Correct tyre pressure is key to reducing truck fuel consumption and tyre wear. Manually adjusting the pressure for each trip and change in weather conditions is a time-consuming task that is often neglected. Wheel bearings from Schaeffler have an integrated seal that helps adjust tyre pressure to driving conditions on the fly – without any manual input from the driver. “This solution reduces fuel consumption, CO2 emissions and tyre wear, which enables fleet operators to lower their operating costs while at the same time improving safety,” explains Dr Dieter Eireiner, Head of Schaeffler’s Bearings business division.

The wheel bearing has a compressed air feed through to the tyre. This is embedded in an OEM system, which enables the pressure in the tyres on all axles to be raised or lowered: for instance, preventing high temperatures increase tyre inflation pressure, which is not only bad for the tyres but also leads to longer braking distances, or when traction is supposed to be enhanced in off-highway applications with low inflation pressures.

The innovative design of the wheel bearing also features a novel type of thermal treatment and a modified sealing concept that reduces friction by 56 per cent, saving up to 600 watts of energy per 13 metric tons of axle load. For a commercial electric vehicle with a 500-kilometre range, this will mean up to 11 kilowatt hours per charging event can be saved in this way, which leads to a reduction in consumption and CO2 emissions of commercial vehicles.

The future of the transportation and logistics sector is electrified, automated and digital, and bearings are a key component with which commercial vehicles will travel the roads more efficiently and safely. Especially in heavy-duty haulage, bearings offer huge savings potential – in both conventional and electrified powertrains. Schaeffler has been developing speciality bearing solutions for light and heavy-duty trucks for 100 years. Going forward, further developments will be focused on bearing solutions for electrified powertrains, automated driving, and digitalisation.