Lubricators

Rolling bearings are automatically supplied with the correct quantity of lubricant by lubricators or lubrication systems. The prevents the most frequent cause of rolling bearing failure: Insufficient or incorrect lubrication. Approximately 90% of all bearings are lubricated with grease. Relubrication with the correct quantity of grease at the appropriate intervals provides a significant increase in the operating life of the rolling bearings.

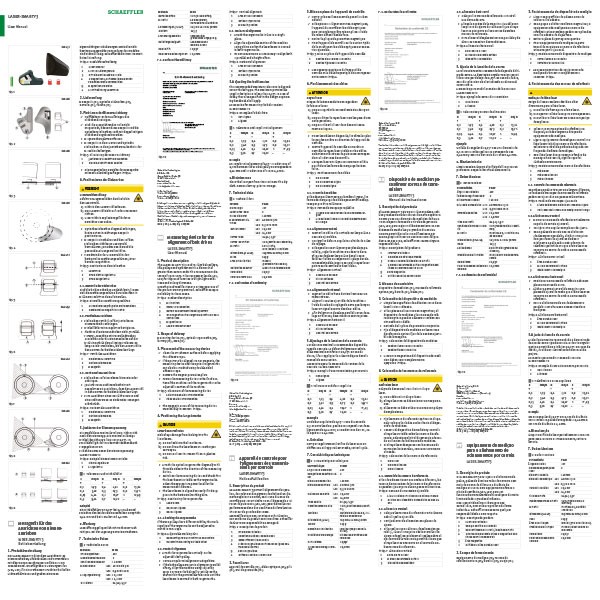

CONCEPT1

CONCEPT1 automatic lubricator

The CONCEPT1 is the most cost-effective starter product for automatic relubrication. It is easy to handle, robust, ATEX-certified, and conforms to protection class IP68. This makes it ideal for a wide range of applications, and it is supplied either pre-filled with Schaeffler’s high-performance ARCANOL grease or as an empty device that can be re-filled multiple times with the customer’s own lubricating grease or oil. This reduces waste, helps protect the environment, and saves maintenance costs.

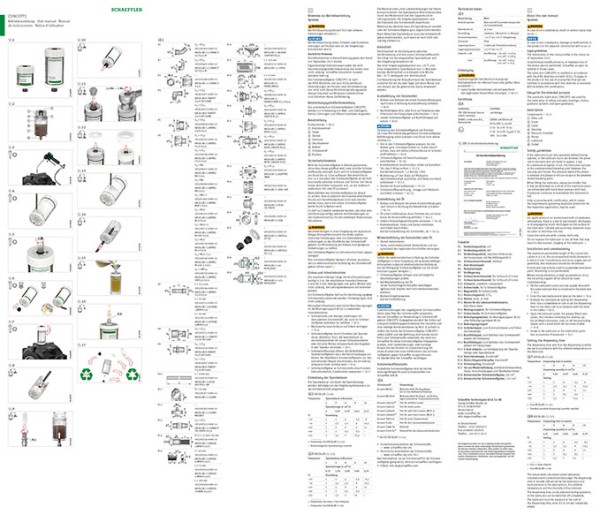

CONCEPT2

CONCEPT2 automatic lubricator

This lubricator is suitable for minimum-quantity lubrication with grease or oil. It has two lubricant supply line outlets that can be controlled separately. The outlets are fed by piston pumps that carry out one dispensing operation per actuation. This dispensing operation can be triggered by internal impulses (via the integrated timer) or external impulses (via the SPS).

The lubricant cartridges (LC units) are available with a capacity of 250 cm3. An integrated multi-functional interface provides a 24 V DC power supply and I/O communication with external control systems. A battery-powered version of the lubricator (without the multi-functional interface) is also available as an alternative.

CONCEPT4

CONCEPT4 automatic lubricator

This lubricator is suitable for minimum-quantity lubrication with grease. It has four lubricant supply line outlets that can be controlled in separate pairs. The outlets are fed by piston pumps that carry out one dispensing operation per actuation. This dispensing operation can only be triggered by external impulses (via the SPS). The lubricant cartridges (LC units) are available with a capacity of 400 cm3. An integrated multi-functional interface provides a 24 V DC power supply and I/O communication with external control systems. The customer-specific version of the CONCEPT4 offers immense potential for OEM customers. When a minimum batch size is defined for every delivery, significant cost savings (TCO) can be achieved (e.g. with regard to the number/design of the outlets and the cartridge sizes. Firmware, device with grease cartridge inserted, fully de-aerated (plug&play), complete packages with lubricant supply lines cut to length/pre-filled, customer-specific branding, and much more).

CONCEPT8

CONCEPT8 automatic lubricator

This lubricator is suitable for minimum-quantity lubrication with grease or oil. It has a maximum of eight lubricant supply line outlets that can be controlled in separate pairs. The outlets are fed by piston pumps that carry out one dispensing operation per actuation. This dispensing operation can be triggered by internal impulses (via the integrated timer) or external impulses (via the SPS). The lubricant cartridges (LC units) are available with a capacity of 800 cm3. An integrated multi-functional interface provides a 24 V DC power supply and I/O communication with higher-level control systems.

CONCEPT refill cartridges for every grease

All cartridges for the CONCEPT lubricators are also available as refillable empty cartridges. This means that the CONCEPT devices can also be operated using third-party greases that are not part of the Arcanol range. Using these cartridges – which can be refilled up to three times – eases the burden on both the environment and your wallet.

They can easily be refilled using a standard grease gun and corresponding adapter. After filling, the cartridge is ready to use and can be fitted to the CONCEPT device.

Service center

All of the essential information about our automatic lubricators can be found in our service center. This service information includes the key application examples for the automatic lubricators, explanatory films, informational material, and instructions for easy installation and operation.

General information

Flyers and brochures

Reference sheets

Relubrication for large-size fans (GTS 0116)

High cost savings through online condition monitoring and automatic lubrication (GTS 0136)

Friction disk spindle bearing failure analysis (GTS 0105)

Effective lubrication makes all the difference (GTS 0115)

FAG CONCEPT8 provides constant lubrication (GTS 0113)

Automatic lubrication systems increase machine availability (GTS 0064)

Coated rolling elements to avoid slippage damage in calender bearings (GTS 0001)

Training courses

Technical documents

Operating instructions

Instructional videos

If you have any questions about our products or services, please contact Schaeffler’s experts.